I love the outdoors. This also has led me down some crazy paths and hobbies. But it has also taught me a lot about different aspects of life. Due to the recent happenings, I have found myself watching more and more Youtube videos than I ever have before. This has led me down many strange paths of information which some have been useful and some have not. We all have a right to waste time, don't we! I do enjoy fixing my home and paying less to do it with the help of youtube tutorials. Although I have been most interested personally with the idea of edge retention on knives and the many different ways that have been used to test it. The fact that it can be quantified at home and have some useful benefits come from it is a lovely thing. So I will go over how cardboard boxes are involved in some youtube channel steel degradation tests. These are more useful now than ever before with the influx of boxes we keep getting at our homes.

How did I get onto this topic? Well, that was because I enjoy using knives and watching youtube. The first channel I found was called Cedric and Ada. This channel was based upon the idea that a single individual could take a household item and use it as a baseline to measure how much certain steel could cut. In this instance, the host would take twisted Cecile rope and test a different knife with different steel and cut until it was dull. The individuals would take the knife and attempt to create the same type of edge on the blade. This meant he would hand sharpen it with the same angle to the exact same specifications as much as he could. Then he would tape off a section of the blade so as to only use the same part over and over. He would then test the sharpness on a piece of paper and then begin cutting the rope. He would cut the rope over and over in little pieces until the knife was no longer able to cut paper. This number would then be stored for each type of steel he was able to acquire.

I am always a fan of repeatable tests that others can benefit from. By creating a repeatable system he would then be able to tell the actual edge retention of different types of steels. This was a fascinating way to see what one was actually paying for and if there are differences in the cost of different steels. Truly there are. I have learned so much and been able to save myself money by not wasting in on bad products.

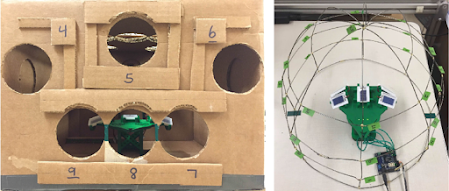

There are also ways to do this. Another channel used a very similar style of the test, but used the excess amount of cardboard boxes to test the edge retention. The host would sharpen each knife to the same specifications and instead of taping off a section, he would then just use the whole edge to cut through the same length of cardboard. Thus at the end being able to quantify different kinds of steel. I found it a wonderful way to know what type of knives and steels are best for certain applications. It is fun to learn new things and to find them useful.